Sintered Wire Mesh from China Manufacturer - Quality & Durability

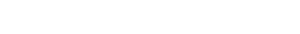

Sintered wire mesh is a game changer for anyone needing durable and reliable filtration solutions. As a manufacturer based in China, we take pride in offering high-quality sintered wire mesh that’s designed to meet rigorous industry standards. Our products are made from multiple layers of woven wire mesh and offer excellent strength, corrosion resistance, and precise filtration capabilities. I know how important it is for your business to find materials that not only perform well but also last long. With our sintered wire mesh, you can achieve superior filtration for liquids and gases, even in the most challenging environments. Whether you’re in the automotive, chemical, or food processing industry, our sintered wire mesh provides the performance you need. Your operations deserve reliable materials, and I’m here to ensure you get just that. Trust us to deliver exceptional products backed by years of experience in manufacturing sintered wire mesh in China. Let’s elevate your filtration processes together!

Sintered Wire Mesh Stands Out in 2025

In 2025, the landscape of industrial materials is evolving, and sintered wire mesh is taking center stage as a preferred choice for various applications across multiple industries. This innovative product stands out due to its unique combination of durability, filtration efficiency, and versatility. Sintered wire mesh is crafted through a meticulous process that fuses multiple layers of wire mesh together, resulting in a robust structure that can withstand extreme conditions. Its excellent resistance to chemical corrosion and high temperatures makes it ideal for sectors such as petroleum, chemical processing, and food processing. Global buyers seeking reliable solutions will find that sintered wire mesh not only meets but exceeds their expectations. Its customizable nature allows for tailored specifications to suit specific project requirements, making it a go-to choice for filtration, separation, and support applications. Additionally, the innovative design promotes enhanced flow rates and reduced pressure drops, increasing operational efficiency. As businesses prioritize sustainability and eco-friendly practices, sintered wire mesh emerges as a cost-effective option that reduces waste and extends the lifespan of equipment. The demand for high-performance materials is on the rise, and sintered wire mesh is well-positioned to meet this need in 2025 and beyond. By investing in sintered wire mesh solutions, global purchasers can benefit from superior quality, improved productivity, and reliability. As industries continue to evolve, staying ahead with advanced materials and technologies will be crucial for success, and sintered wire mesh is a key player in this transformation.

Sintered Wire Mesh Stands Out in 2025

| Feature | Description | Applications | Key Advantages |

|---|---|---|---|

| Material Composition | Stainless steel, bronze, and other alloys | Filtration, separation, and support applications | Corrosion resistance and durability |

| Mesh Size | From 1 micron to 10 mm | Oil & gas, water treatment | Versatility in various applications |

| Manufacturing Process | Sintering and rolling | Aerospace, automotive | Uniform porosity and structure |

| Temperature Resistance | Up to 1000°C | Chemical processing | High thermal stability |

| Customization | Tailored sizes and shapes | Food processing, pharmaceuticals | Meeting specific industry requirements |

Related Products