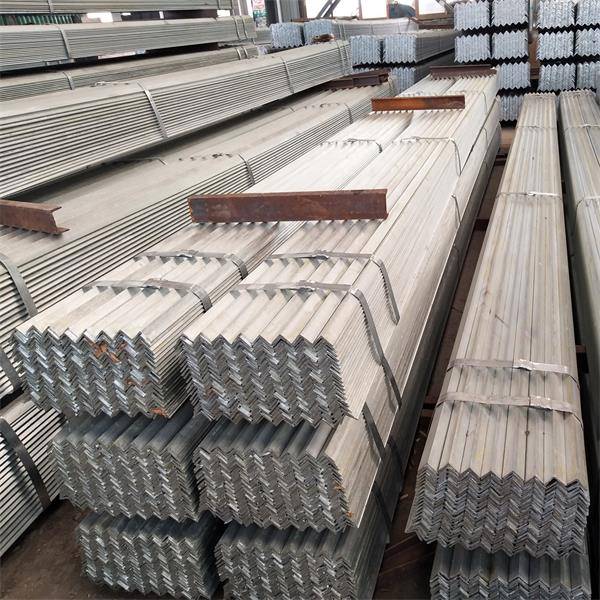

Top China Manufacturer of Galvanized Barbed Wire - Quality You Can Trust

As a manufacturer of high-quality galvanized barbed wire in China, I understand the needs of B2B purchasers like you. Our galvanized barbed wire offers exceptional durability and resistance to corrosion, making it ideal for various applications, from agricultural fencing to securing construction sites. I know that sourcing reliable materials is crucial for your projects, and that's why our product goes through rigorous quality checks to ensure it meets international standards. Plus, the barbs are designed for maximum effectiveness, providing that extra security you need. When you choose our galvanized barbed wire, you’re not just getting a product; you’re investing in peace of mind and reliability. Our competitive pricing and flexible order quantities cater to your business needs. If you’re interested in boosting your fencing solutions with our top-notch products, let’s discuss how we can meet your requirements efficiently.

Galvanized Barbed Wire Manufacturer Winning in 2025

As we approach 2025, the demand for robust and reliable security solutions continues to rise globally. Among these, galvanized barbed wire stands out due to its durability and effectiveness in securing properties against unauthorized access. This trend is particularly significant for industries focused on agriculture, construction, and perimeter security. Manufacturers who prioritize quality, innovation, and sustainability are well-positioned to capture a larger share of this expanding market. In a world increasingly concerned with security and safety, galvanized barbed wire manufacturers that embrace advanced production techniques and environmental responsibility will thrive. Utilizing high-quality raw materials and state-of-the-art manufacturing processes not only enhances product performance but also addresses the growing consumer demand for sustainable practices. This shift empowers businesses to meet the distinct needs of global buyers seeking reliable and eco-friendly security solutions. Looking ahead, manufacturers that invest in research and development to innovate their product offerings, while also ensuring compliance with international quality standards, will gain a competitive edge. Building strong relationships with global distributors and prioritizing customer service will further solidify a manufacturer’s reputation in the market. The future of galvanized barbed wire manufacturing promises substantial opportunities for those ready to adapt to the evolving landscape of both security needs and sustainability expectations.

Galvanized Barbed Wire Manufacturer Winning in 2025

| Category | Material Type | Diameter (mm) | Coating Thickness (µm) | Tensile Strength (MPa) | Application Area |

|---|---|---|---|---|---|

| Standard | Galvanized Steel | 2.5 | 50 | 600 | Perimeter Security |

| Heavy Duty | Enhanced Galvanized Steel | 3.0 | 70 | 900 | Military Installations |

| Economical | Bared Steel | 2.2 | 30 | 500 | Agricultural Fencing |

| Premium | High Carbon Steel | 3.5 | 100 | 1200 | Industrial Use |

Related Products