RAZOR BARBED WIRE

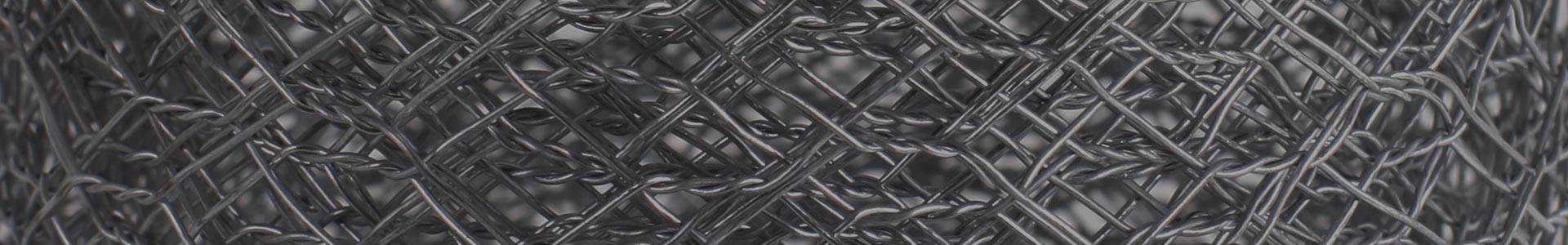

The multiple blades of a razor-wire fence are designed to inflict serious cuts on anyone attempting to climb through and therefore have a strong psychological deterrent effect. Razor wire is used in many high-security applications because, although it can be circumvented relatively quickly by humans with tools, penetrating a razor-wire barrier without tools is very slow and difficult, giving security forces more time to respond.

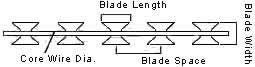

Razor barbed wire has a central strand of high tensile strength wire, and a steel tape punched into a shape with barbs. The steel tape is then cold-crimped tightly to the wire everywhere except for the barbs. Flat barbed tape is very similar, but has no central reinforcement wire. The process of combining the two is called roll forming.

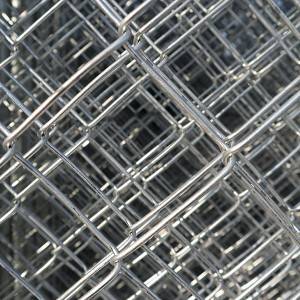

Razor barbed wire is available as either straight wire, spiral (helical) coils, concertina (clipped) coils, flat wrapped panels or welded mesh panels. Unlike barbed wire, which usually is available only as plain steel or galvanized, barbed tape razor wire is also manufactured in stainless steel to reduce corrosion from rusting. The core wire can be galvanized and the tape stainless, although fully stainless barbed tape is used for permanent installations in harsh climatic environments or under water.

Barbed tape is also characterized by the shape of the barbs. Although there are no formal definitions, typically short barb barbed tape has barbs from 10-mm to 12-mm long, medium barb tape has barbs 20-mm to 22-mm long, and long barb tape has barbs from 60 to 66-mm long.

specification:

|

Ex. Dia. |

No. of Turns |

Standard Covering Length |

Production Model |

Remarks |

|

450mm |

33 |

8M |

CBT-65 |

Single coil |

|

500mm |

41 |

10M |

CBT-65 |

Single coil |

|

700mm |

41 |

10M |

CBT-65 |

Single coil |

|

960mm |

53 |

13M |

CBT-65 |

Single coil |

|

500mm |

102 |

16M |

BTO-12.18.22 |

Cross type |

|

600mm |

86 |

14M |

BTO-12.18.22 |

Cross type |

|

700mm |

72 |

12M |

BTO-12.18.22 |

Cross type |

|

800mm |

64 |

10M |

BTO-12.18.22 |

Cross type |

|

960mm |

52 |

9M |

BTO-12.18.22 |

Cross type |